Tweet

Translations:

Català

中文 / Zhōngwén

English

Español

Français

Ελληνικά / Elliniká

Italiano

Português

Română

Српски / Srpski

Türkçe

Other formats:

Other Pages:

Modules

Site Map

Key Words

Contact

Utility Documents

Useful Links

Contents:

Contents:

Contents:

Contents:

Contents:

Contents:

Contents:

Contents:

CONSIDER THE ROPE PUMP

Assisting Communities to Do Things for Themselves

By Phil Bartle, PhD

Dedicated to Andrew Livingstone

Training Handout

Why not design a pump that uses only locally available parts?

Introduction:

This is not an engineering document, but it is about a piece of engineering technology, a humble pump for bringing water up from shallow wells. See Internet References. Like the other training documents on this web site, this one is based upon the principle that communities can best be strengthened (empowered) by doing things for themselves rather than waiting for outside charity.

The technical or engineering aspects are meant to be used as an illustration of that principle.

The rope pump, now popular in Central America, has several advantages and drawbacks. The discussion here is focused on how these can illustrate the empowerment approach for low income communities. While it is aimed at the community mobilizer, engineers and technicians may find it amusing.

Rope Pump:

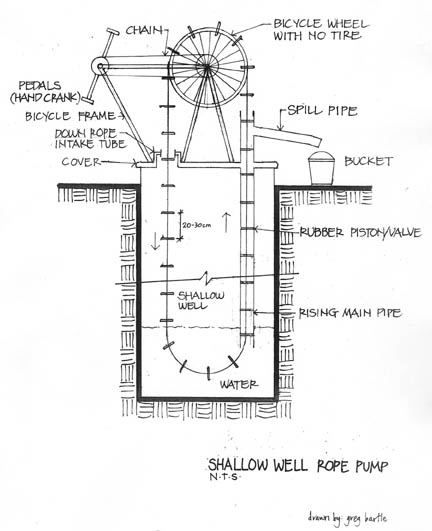

The rope pump is quite simple. It consists of a continuous loop of rope. It is wrapped around a bicycle wheel at the top of the well. See the diagramme.

It hangs loose down into the well, and then is brought up through the inside of a plastic pipe to the top again. On the rope are attached valves, made from used inner tubes (or any suitable flexible material such as used shoe leather), every 20 to 30 cm. The bicycle wheel can be cranked by hand so that the rope moves down the outside of the pipe and then up again inside the pipe. A bicycle frame can be modified by a welder and with a hacksaw to hold the bicycle wheel, and the foot pedals modified to become a hand crank. As the rope comes up the inside of the pipe, the valves push water from the bottom of the well to the top. A junction is made into the pipe near the top so the rope continues up to the wheel while the water spills out of the pipe to a waiting container.

Simple.

All the components of the rope pump are usually available in any medium sized town: rope, used inner tubes, used bicycle frame and wheel, and plastic pipe. None is very expensive.

The rope pump has been around for years, perhaps decades, but in the past few years it has become popular and widely used in Nicaragua.

Water Technology is Not Rocket Science:

For more than a half century, aid projects from Europe and North America, or through multilateral agencies, have been providing assistance aimed at bringing potable water to rural communities in Africa, Asia, South America and elsewhere that low income countries are found. During all that time, while western technology has put a human being on the moon, developed the internet and the cell phone, and uncovered secrets of human DNA and sub molecular entities. It has not, however, found a way to provide rural water for poor villagers that will last beyond the outside help more than a few months, or a year or so maximum.

Hand pump technology was developed for single family use in Europe and North America, and appears to be unreliable for communal service to 500 or so villagers, no matter what technical improvements have been made, or how much training is provided. That technology has failed because its inventors and developers are missing some things about the values, behaviour and organization of the people who need the water. Or is it that the manufacturers make a profit from the sales of spare parts and do not want to build pumps that will last longer?

Once a particular hand pump is chosen by the authorities, it makes economic sense to try to ensure that all hand pumps installed in a region are the same, so they will require the same set of spare parts. That way, the manufacturer gets a captive market for the spare parts.

The Spare Parts Conundrum:

Making spare parts available and inexpensive for rural communities is a big problem. Cheaper and fast moving (high inventory turnover) spare parts would be less of a problem, because local dealers would be willing to stock them. Private enterprise may be able to handle the situation.

Larger and slowly moving parts are not so popular with dealers because they cost money to store and are not profitable to sell. The market is too narrow. Attempts are made to obtain governmental subsidies for those spare parts, or at least some free storage.

The question has been posed, then, as to how many pumps (of the same type) must be constructed in an area so that the spare parts will move fast enough to make it a profitable business for free enterprise. What is the threshold number? The wider the market, the more viable the sales of spare parts.

Economists have suggested that the way to make the supply of spare parts profitable is that the spare parts be also used for other purposes. Valves and bearings, for example, that are made to be used on motor vehicles will be stocked for a much wider market than for use only on hand pumps. Bearings and valves for the renowned Afridev hand pump, for example, are made in sizes and shapes that they are useful only on Afridev pumps. A very narrow market. Some efforts are being made to design new hand pumps that can use spare parts already available for other markets. A wider market is more viable and sustainable.

The rope pump, of course, has all its spare parts, the whole machine, available in several other markets widely spread through the areas of our interest (poor countries). Some of them, broken bicycles and used rubber tires, for example, are even found abandoned on rubbish heaps. Finding them can be a good business for recyclers and gleaners.

Vested Interests:

Many persons in positions of power, authority and expertise have vested interests in keeping the situation the same as it is now. Hand pump technology is a lucrative manufacturing business for factories in Europe and India, or in countries where subsidiaries have been set up.

While the raw materials for hand pumps are fairly common, by making them into a hand pump, a manufacturer adds considerable value to them, and therefore makes an admirable profit from their sales. The possibility that a viable pump can be made totally from local materials by artisans who can already make other things from them, strikes fear into the hearts and pocketbooks of hand pump manufacturers and their champions.

People who want to keep things the way they are will hire and/or subsidize experts and writers, to try to find fault with local alternatives such as rope pumps, and to sing praises of their own designs of hand pumps. They will also be tempted to provide gifts and incentives to governmental authorities to create rules and regulations that favour the use of hand pumps (eg their own) over locally created alternatives.

Keeping things they are the way now perpetuates poverty and dependency

Ah, Yes! Corruption:

In the training module about reducing poverty, one of the five major factors of poverty is listed, dishonesty.

If a civil servant diverts investment or development money from its intended purpose and into her or his pockets, it is dishonest. It is a factor contributing to the sustaining of poverty.

There is a multiplier effect. The money intended for development is investment money; it would contribute to an increase in future real income. When it is diverted by a civil servant for personal use (stolen), it is also converted from investment to consumption. That means, for example, that a hundred units of currency intended for development would be worth six or seven hundred units of future increase in communal wealth. That six or eight hundred units of currency is stolen from the community whereas the corrupt official gets only the one hundred units for personal use (and which she or he can put into circulation in the local economy). Even the one hundred units will be lost to the local economy if it is transferred to a foreign bank account – as in Switzerland.

In the water and sanitation sector, the use of bore holes and hand pumps offers several opportunities for such diversion.

When a commercial business is hired to drill the bore hole, or to install the hand pump, it will charge a large amount for the facility and for the labour in installing it. If the recipient village is remote, the villagers illiterate and fearful of authorities (so less likely to complain), and if no monitoring is done, then the company can save a lot of money (for labour and the non-installed equipment) by not providing it, yet reporting that it has been provided. The company would then give a share of those large savings to the appropriate government official to avoid reporting the crime. When the bore hole is machine dug, and where the hand pump is imported or manufactured in the capital city, this is a relatively easy way to divert development funds.

Some people are apologists for such diversion of resources by civil servants, saying that their salaries are too low. How does that genuinely justify criminal activity? If a villager stole merely ten dollars worth of local goods, she or he would be beaten, perhaps to death.

If civil servants' salaries are too low, they should be reset at market rates minus the value of the extra perks of civil servants, job security, housing subsidy, and so on. Their position of privilege in the government should not be a reason to overlook any crime they commit, especially thefts of large amounts of resources meant for poor people. Low salaries should never be used to explain theft and dishonesty. These are crimes. They happen more where there is less transparency of governmental expenditures.

In contrast, where the well is hand dug using local labour (paid out of the same development or investment funds), and where the pump is made totally out of local material (as for a rope pump), then diversion is much harder to hide, therefore much more difficult to accomplish.

Government authorities and national business people thus have even more reason to find faults with alternate technology and argue against their use.

Drawbacks:

Like most things in life, the rope pump is not a package of unmitigated joy and happiness. There are a few drawbacks. These include depth limitations and possible water contamination.

While the rope pump is effective for shallow wells, it is less effective for deeper wells. Unfortunately, it is not easy to predict how deep a well can be in which a rope pump will work.

The unpredictability arises from the use of local materials with no universal standards. Both the diameter and thickness of the valves, for example, affect how deep a well may be (on which to put a rope pump). Because inner tubes and leather come in several thicknesses, and because the valves are cut by hand by local artisans, they are not uniform. If the valve is too thin and flexible, it bends and releases water down to the valve below it on the rope.

As wells are more deep, the water weighing on the bottom valve may be so heavy that it all leaks down before it can be brought to the top of the well. Similarly, even if it is not too flexible, it may not be cut to precisely the diameter of the inside of the pipe, and water will again leak to the valve below. This problem, too, increases with the depth of the well. If the valve is cut to fit too tightly against the inside of the pipe, in contrast, it might more effectively bring the water up the pipe, but that might also add to the difficulty of cranking the wheel at the top. At some point the wheel will be too difficult to turn by hand. This problem, too, increases with the depth of the well.

Since these are unpredictable variables, it is not yet possible to state what is the maximum depth of well on which a rope pump will be effective. Perhaps it is 35-45 metres.

Another drawback is a potential for well contamination. The rope pump described above does not indicate that the well should be covered. There is a tendency for local people to omit covering the well, because that takes time, money, effort and desire (based on hygiene knowledge). If the well is uncovered, little animals can get into it and defecate or die or both. Human wastes and parasites can even find their way into the well if hands are not clean when the wheel is cranked.

A good well cover will allow the pipe to come up above it, before diverting the water pulled up by the upcoming rope to a container. A simple hole in the cover for the down going rope may be satisfactory. It will certainly be improved by installing a short piece of pipe, a little wider than the main pipe, above the cover, so that the valves can easily go into it, along with the rope, back down into the well.

When the residents of the community are not so concerned about hygiene (the norm, unfortunately, rather than the exception), and short on resources, they may be more tempted to omit the cover, thus allowing an increased potential for well contamination.

Appropriate training and effective hygiene public awareness may decrease the effects of these drawbacks.

While these are recognized drawbacks to using a rope pump, they are not major problems. Experts with vested interests in using hand pumps, however, will exaggerate them, and omit telling you that the costs of dealing with such minor drawbacks are far lower than the costs of using hand pumps.

Increasing Labour Intensity:

Local unskilled labour can be used to dig shallow wells, and to install the rope pumps onto the well heads. Skilled labour, as independent artisans, can make valves out of used tires, construct the pump out of used and abandoned bicycles, and put valves onto the rope.

Spending development money on local labour instead of on imported capital has many advantages. Earlier it was argued that it reduces opportunity for diversion of funds for personal use, which is a function of increased transparency by having more people involved. Transparency helps money raised by the community and money coming from donor agencies to be more visible, and therefore less likely to be diverted.

It also has other advantages. As part of a process of strengthening private enterprise, local well digging and rope pump manufacturing enterprises can be formed and trained. That organizing can be part of the job of a community mobilizer (you).

The development money that would leak out of the community if it were spent on importing a hand pump manufactured elsewhere, would go to these locally organized business enterprises. A well digging company or co-op could be formed with a core of managers and trainers (from the district or province) who hire a different set of local labourers for each client community well (from each client community where a well is to be dug).

When the money is used to give employment to local youth, the money they earn will be spent by those youth in local purchases of consumer goods by them. That, in turn, stimulates the economy because it is an infusion of new money that would otherwise go out again to buy imported capital goods and/or to pay drillers and suppliers from outside the community.

The same applies to the employment of local artisans to convert old broken bicycles into the pumps, to convert used tires into valves, to attach valves to the ropes, and to cut and install the plastic piping. The technology of the rope pump lends itself well to increased labour intensity, to increased local income generation, reduction of unemployment, and the development of local business.

Mobilizer Strategies:

This document, like others in the series, is aimed mainly at community mobilizers (and their managers and planners). It is not intended as a technical treatise on rope pumps, but rather as a discussion of social and economic considerations related to using them.You, as a mobilizer, animator, activist or community worker have, as your main purpose, the strengthening (capacity development) or empowerment of poor communities.

Self reliance is not only a freedom from depending upon outside funds, but is also a freedom from all sorts of outside resources (including ideas about what technologies to use). There is no evidence that poor villages in less developed countries need to adopt unquestioningly the thinking, creativity and assumptions on which the technology of Europe and North America are based. That is a form of mental dependency that is a factor in sustaining poverty.

The provision of expensive bore holes and expensive hand pumps also creates a form of dependency. Where aquifers are too deep, such dependency can not be avoided totally (probably). Where aquifers are deep, however, the water is more likely to be salty, and pumping too difficult, so that is where other labour intensive technologies should be considered, such as rain water harvesting. Where aquifers are not so deep, bore holes and hand pumps can be avoided.

By promoting the use of rope pumps, explaining their advantages and disadvantages to community members who must decide if they want them, the mobilizer can help reduce dependency and help improve self reliance. If they are seen to work, they will be copied.

Remember that it is the village, not the agency, which must make the decisions. While you can review the costs and benefits of various choices with them, community members, as a group, must decide what level of technology would be most appropriate for them. Armed with the arguments and considerations above, you can assist them with considering the consequences of choosing a rope pump in contrast with other technologies. Your strategy is to lay out alternatives, costs, benefits and other considerations of each, so that community members as a group can make informed decisions for themselves.

Conclusion:

Rope pumps are not a universal panacea to cure all the ills of the potable water sector. They do, however, improve the situation for a lot of problems now occurring.

While there are powerful vested interests that will resist the introduction and growth of the use of rope pumps, their advantages, especially in supporting increased community self reliance and empowerment, far outweigh their drawbacks.

The mobilizer is in a good position to suggest the introduction of rope pumps, to facilitate their increased use, and help community members to make their own decisions and to help themselves and to become more empowered.

––»«––

Some web addresses:

- http://www.i4at.org/lib2/ropepump.htm

- http://www.ropepump.com/

- http://home.planet.nl/~holts000/index.htm

- http://www.gaia-movement.org/ (pdf)

- http://www.gamos.demon.co.uk/

|

|

| Click on diagramme for full size |

|

|

| Students Make Rope Pump at Science Fair |